The science behind site investigation

03 Jun 2019

Geoenvironmental

Geotechnical

Following an invitation from i2 Analytical, a team of Delta-Simons geo-environmental professionals embarked upon a tour of their chemical and geotechnical laboratory in Poland.

Founded in 2013, i2 Analytical are one of Europe’s leading independent environmental testing companies and are the sole providers of soil, rock and water testing to Delta-Simons, chosen for the extensive UKAS and MCERTS scope of accreditation, professionalism and customer focus.

The main purpose of an intrusive site investigation is to better understand the ground and geo-environmental testing helps to support this. During a site investigation, soil and groundwater samples are usually collected for geo-environmental testing to provide information to assess the contaminative status of the site and provide information for geotechnical design parameters.

Contamination issues have the potential to cause an unacceptable risk to human health and controlled waters, and geotechnical issues may include soft ground with a low bearing capacity for example.

In order to comply with the requirements of the regulators it is necessary to send soil samples to a laboratory which can undertake chemical and geotechnical analysis in accordance with British/European standards and at the same time still maintain UKAS/MCERTS accreditation for the UK regulators.

Environmental Sampling

The sampling requirements are normally determined at enquiry and desk study stage, once the Site proposals are understood and current and historical site uses are reviewed and we know where to target specific ‘sources’ of contamination (e.g. the location of a former underground storage tank). The sampling frequency and subsequent suite of chemical tests scheduled is dictated by several factors including:

The sampling requirements are normally determined at enquiry and desk study stage, once the Site proposals are understood and current and historical site uses are reviewed and we know where to target specific ‘sources’ of contamination (e.g. the location of a former underground storage tank). The sampling frequency and subsequent suite of chemical tests scheduled is dictated by several factors including:

- The client and brief – are they a vendor or purchaser? Is it pre-acquisition or divestment?

- Is it to support a planning application or to discharge a specific planning condition?

- The nature of the development – residential, commercial or industrial?

- Is it for preliminary advice, detailed testing for development of a remediation strategy, validation testing or waste disposal?

A Conceptual Site Model is derived at desk study stage to identify possible sources of contamination and potential receptors. For an actual risk to be present there has to be a pollutant linkage present and the environmental testing enables a quantitative risk assessment of previously identified plausible pollutant linkages to be undertaken based on current UK standards Soil Guideline Values (SGVs) and Generic Assessment Criteria (GACs).

Geotechnical Laboratory Testing

Geotechnical Laboratory Testing

Intrusive site investigations are also used to investigate the geology and engineering properties of the ground. The engineering properties can be tested through in-situ testing and/or laboratory testing and the results are used by engineers for feasibility purposes and the detailed design of foundations, roads, earthworks and other infrastructure such as bridges, flood defences and railways.

Depending on the geotechnical tests undertaken, the results can be interpreted directly or used to derive other geotechnical parameters.

How does the relationship work?

i2 pick the samples up from the Delta-Simons regional offices in the UK or directly from the site of origin, with engineers also electing to drop off samples where convenient. Samples are then transported to the appropriate receiving facility for registration – Watford for Chemistry/Environmental testing and Northampton for Geotechnical. At this point i2 can check through the samples and associated testing instructions to ensure everything is in place, with the samples either subsampled or immediately packed and taken via one a fleet of vehicles to the analytical laboratory in Poland for analysis.

Once the samples reach the laboratory in Poland, analysts work across three shift patterns from 6am to 10pm to ensure the production of robust and quality assured data for reporting.

The Poland Tour

The tour began where the soil and water samples are delivered at the laboratory and strategically sorted depending on the type and test requirements. Where samples are required on a quick turnaround i.e. less than five days, a specialist area is clearly segregated and samples on the quicker turnaround are taking to the relevant benches for expedited preparation.

We then went on to view various laboratories where pH, sulphates, heavy metals, PAHs, TPH and other determinants were being analysed. Delta-Simons engineers were given the opportunity to screen soils for asbestos fibres and, by the use of polarising light microscopy, were able to differentiate different types of asbestos fibres.

We then went on to view various laboratories where pH, sulphates, heavy metals, PAHs, TPH and other determinants were being analysed. Delta-Simons engineers were given the opportunity to screen soils for asbestos fibres and, by the use of polarising light microscopy, were able to differentiate different types of asbestos fibres.

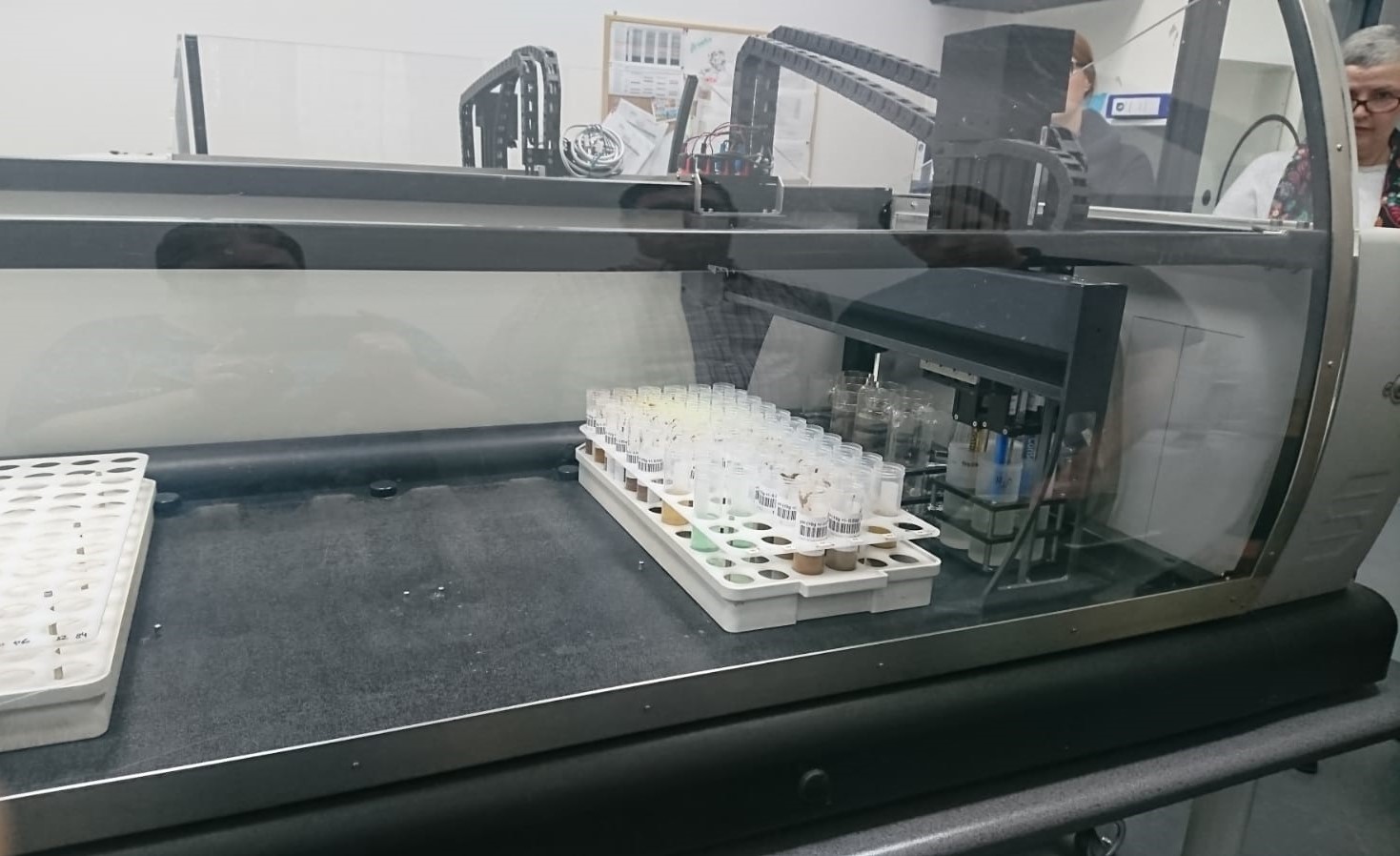

As expected, the chemical laboratory was very impressive with high tech computers, machines and robots with numerous banks of GCMS machines including the first GCMS that the company owner (Les Jones) used to set the company up in Poland. One of the lasting images when walking around the laboratory was the degree of automation that was possible for chemical analysis, in some cases several hundred samples being loaded onto one machine allowing continuous and efficient operation of sampling equipment, whilst at the same time making provision for the relevant blanks, trip blanks, spikes and reference materials to be processed. This ensures that the high level of precision and accuracy is maintained throughout the operation to provide clients with reliable information.

Following a delicious home-made lunch made in the i2 canteen, we saw the geotechnical laboratory which is far more manual than the chemical laboratory. We witnessed Particle Size Distribution (PSD) and sedimentation tests, liquid and plastic limits, CBR and compaction testing. Again, we were struck by the manual labour that was required to undertake a simple test such as the plastic limit test, with employees demonstrating amazing patience and dedication due to the requirement to continuously roll out 10mm long 2mm diameter sausages as part of the tests that we commonly refer to as Atterberg limits.

Following a delicious home-made lunch made in the i2 canteen, we saw the geotechnical laboratory which is far more manual than the chemical laboratory. We witnessed Particle Size Distribution (PSD) and sedimentation tests, liquid and plastic limits, CBR and compaction testing. Again, we were struck by the manual labour that was required to undertake a simple test such as the plastic limit test, with employees demonstrating amazing patience and dedication due to the requirement to continuously roll out 10mm long 2mm diameter sausages as part of the tests that we commonly refer to as Atterberg limits.

We also saw banks of apparatus used for consolidation and strength testing and saw the area where rock testing and soaked/unsoaked CBRs were undertaken. During our tour we were suitably impressed by i2’s dedication to the recycling of old equipment and the innovation that was constantly being employed to facilitate new storage solutions or enable the construction of the new RED geotechnical laboratory.

We would like to thank i2 for our time in Poland which was enjoyable and informative. We all learnt something new and it was a pleasure to meet you all and put faces to names that we communicate on an almost daily basis.